Precompound FKM

Review

Description

Precompound FKM

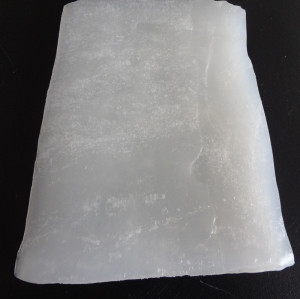

Precompound FKM is the copolymer ofHexafluoropropylene (HFP) and Vinylidene Fluoride, with curing system. It hasgood processing and excellent compression set, and used for producing o-ring,gasket, hose and seals etc.

Grade | Fluorine content% | Density g/cm3 | Mooney viscosity | Compression set | Application |

ML (1+101 21℃) | 200℃×70H (%) | ||||

Bisphenol Curing System | |||||

FL-2660 | 66 | 1.81 | 65 | 16 | Excellent compression set,suitbale for O ring and gasket etc. |

FL-2640 | 66 | 1.82 | 40 | 15 | Good processing and compressing |

FL-2630 | 66 | 1.82 | 35 | 16 | Good metal bonding, processing |

FL-2620 | 66 | 1.82 | 30 | 14 | Good processing performance and Rheological properties, suitable for O ring and shaped ring. |

FL-2462 | 66 | 1.85 | 25 | 15 | Excellent resistance of methanol |

FL-2464 | 66 | 1.85 | 45 | 14 | Good metal bonding, processing |

Package、storage and transportation:

(1). Fluoroelastomer is packed in PE bagsin the form of flake, and then packed into carton with net weight 25kg per carton.

(2). Fluoroelastomer should be stored in clean, dry and coolwarehouse. It can be transported as non-hazardous chemicals and should be far away from pollution sources, sunshine as well as water during transportation.

(3). It issuggested that Flurine fluoroelastomer storing time limit should be one yearafter production. If exceeding one year, these products should be retested,they could be used continuously after being retested up to grade.

Fotech offers high-quality FKM precompound and FKM compound, and could produce according to customer's requirement specially. It is widely used as substitution for DuPont, Dyneon and Daikin FKM.